MOU Transparency of Aluminium Can

MOU signing for “Transparency of Aluminium Can Closed-Loop Recycling” supports the creation of a comprehensive recycling system for used aluminium cans in Thailand.

It’s undeniable that consumption leads to waste, but historically, producers have been focused solely on meeting consumer needs, without considering the waste management after consumption. Greenpeace Thailand discovered that, in Chiang Mai and Chonburi provinces, the largest amount of plastic waste came from major manufacturers for the second consecutive year.

This business model is known as the “Linear Economy,” which is about taking resources to make products that are disposed of after use, without being reused. We can already see the consequences: it has led to wasteful resource use and the failure to manage a massive amount of waste.

A new economic model has emerged to solve these issues, known as the “Circular Economy” Its key principles include reducing the use of new materials, maintaining the value of products and materials for as long as possible, and minimizing negative impacts.

This requires producers to be involved in every phase of a product’s life cycle. That’s where the concept of “EPR” comes in, to help push the Circular Economy to expand even more.

EPR (Extended Producer Responsibility) is the principle of extending the responsibility of producers to the various stages of a product’s lifecycle. Producers must consider the full environmental impact from production to post-consumption, which includes design, distribution, collection, and take-back for recycling or reuse, as well as the management of used packaging.

Many might think that just organizing waste systematically and maximizing recycling can help, but it’s still difficult to prevent waste from escaping into the environment if producers don’t participate from the start. Importantly, the burden of waste disposal shouldn’t fall solely on consumers, some of whom may not even know the correct ways to dispose of waste.

Moreover, end-of-life waste management is getting worse everyday, as most of the waste consists of non-recyclable plastics that ultimately end up in landfills or even into the sea. So, it’s time to shift our focus from just end-of-life waste disposal to caring for products and packaging from the start. This involves designing packaging to minimize waste and extending the lifespan of materials.

To illustrate how EPR can be applied to products and services, we have examples from abroad to show you.

In South Korea, plastic water bottles are now sold without labels. The South Korean government has started a project requesting beverage companies to redesign their packaging by removing all plastic labels from the bottles, turning them into clear, label-free bottles. Many companies have cooperated by switching to embossing directly on the bottle or using laser engraving to reduce the use of PVC labels. To date, there are already 9 brands in South Korea that have switched to label-free bottles.

This is an example of EPR in action to reduce waste from non-recyclable plastic labels by eliminating these components from the start, preventing them from becoming valueless waste later on.

In Germany, there is a deposit refund system (DRS) for various drink containers that can be reused or recycled. The packaging label specifies a separate price for the drink and the packaging. When consumers return the packaging to a RVM (Reverse Vending Machine) for plastic recycling or return the empty containers to the store where they were purchased, they receive a refund for the packaging cost. This acts as an incentive for consumers to return packaging waste to the producers, proving to be highly effective.

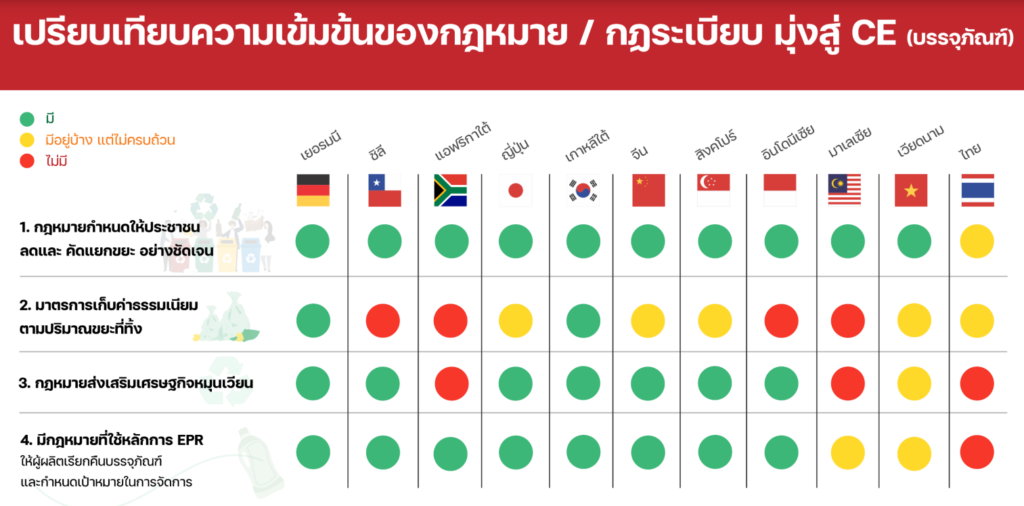

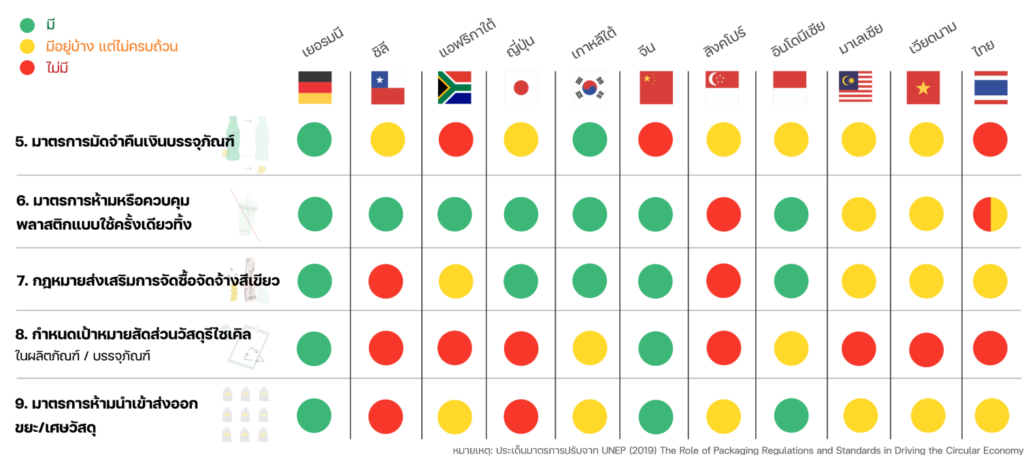

Looking back at the direction of packaging management in Thailand, it is still unclear both in terms of legislation and various measures, such as laws mandating waste sorting by citizens, measures to charge fees based on the amount of waste discarded, and measures to control single-use plastics.

While other countries like Germany, Japan, South Korea, and even ASEAN countries like Singapore, Indonesia, Malaysia, and Vietnam, have clear responsibilities for citizens to reduce and sort waste in their main laws, which form the legal foundation for waste management processes.

Furthermore, ASEAN countries like Singapore and Vietnam will begin implementing EPR laws for packaging within the next two years. However, in Thailand, the concept of EPR is still not widely known. Voluntary EPR by producers is just beginning to be discussed, while globally, there are already 65 EPR systems for packaging, with 45 of them being mandatory.

However, some private sectors inThailandhave started to implement the principles of the Circular Economy, which is part of the overall picture of EPR. Examples include the Take-back projects in cooperation with retail stores or organizations, and various small refill stations across the country.

From the perspective of producers in Thailand, most agree with the legislation to promote the Circular Economy using the principles of EPR. The government should also be involved in pushing this forward, and importantly, accelerate the creation of infrastructure to support waste separation in each region before it goes to recycling plants.

As for consumers, most agree that Thailand should implement laws to manage packaging using EPR principles and are beginning to cooperate in separating waste from the source. However, providing education is important and must come first. Aluminium Loop aims to be a medium that helps convey knowledge and necessary information about packaging so that readers have data to guide their decisions.

From all that has been said, it’s clear that the Circular Economy and EPR must go hand in hand, with the primary goal of reducing environmental impacts from waste, refuse, and various pollutants. Every sector must cooperate, including the government, production, and consumers. Producers have an increased role to be responsible for managing the lifecycle of their products and packaging more carefully and strictly than before.

Thank you to the seminar on “The Direction of Packaging Management in Thailand and the Role of the Industrial Sector”

By Dr. Sujitra Vassanadumrongdee, Environmental Research Institute, Chulalongkorn University.

MOU signing for “Transparency of Aluminium Can Closed-Loop Recycling” supports the creation of a comprehensive recycling system for used aluminium cans in Thailand.

“Eternal Bloom” upcycled aluminium cans waterfall was displayed in front of Central Embassy shopping center to celebrate the 75th anniversary of Central Department Store.

TBC Ball’s initiative to make drink cans a sustainable packaging option, particularly from an environmental perspective.