MOU Recyclable Beverage Packaging

MOU signing ceremony for promoting the production of recyclable beverage packaging between the public and private sectors.

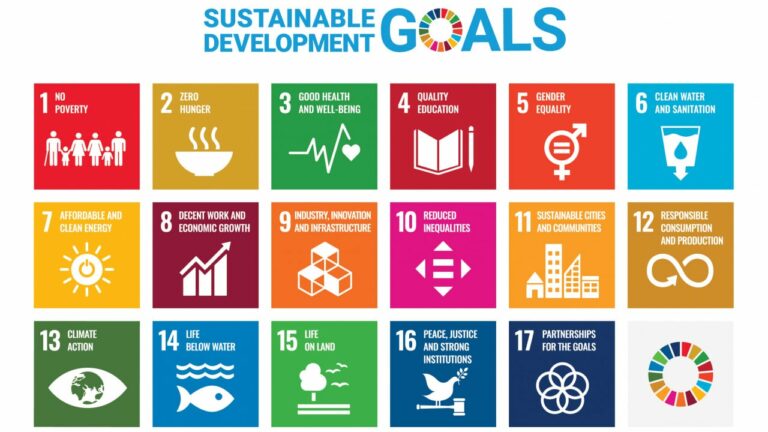

What are SDGs? Many people may have already seen this word due to the current global trend toward the direction of sustainable development. However, how do we achieve sustainability? First, we need to dive into understanding what SDGs are all about.

SDGs stands for “Sustainable Development Goals” that all 193 country members of the United Nations, including Thailand, mutually signed the 2030 Agenda for Sustainable Development to make the world a better place by 2030.

Sustainable Development is a way of development that meets the needs of the present generation without compromising the ability of future generations to meet their own needs (Brundtland Report, 1987).

The achievement of Sustainable Development Goals requires three key elements: social inclusion, economic growth, and environmental protection.

These 3 elements reflect the “Three Pillars of Sustainability” including People, Prosperity, and Planet. However, the other two important dimensions that link all elements together are Peace and Partnership. In total, there are 5 dimensions (5Ps), each of which covers 17 different development goals as follows:

The Sustainable Development Goals (SDGs) are considered inclusive development goals aimed at transformation and integration where every country has various contexts that must be implemented differently.

The development of the country towards UN SDGs requires close cooperation of the government and the private sector. The private sector plays a key role in shaping the consumption of the people in the country and is the main cause of many environmental impacts. Many industries have direct effects on greenhouse gas emissions, global warming and waste creation, stemming from the production processes and the products and packaging produced. Manufacturers need to be mindful in designing their products and packaging, to minimize the negative impacts on the environment and to enhance the economic value to society.

Today, Aluminium Loop invites all readers to explore the aluminium can manufacture business to see how producers consider the SDGs and which goals they are meeting.

Goal 1 No Poverty:: Aluminium cans are made from mono-material, allowing for simple and effective recycling processes. As aluminium is infinitely recyclable, used aluminium cans are in high demand and command a high value as compared to other packaging waste. This can be a good source of income for collectors and purchasers of recyclable waste in the informal waste sector.

Goal 3 Good Health and Well-Being: Food safety and consumer health are of utmost importance in the production of aluminium packaging. Aluminium packaging provides an airtight seal that prevents any contaminants to the beverage once packed. The inside of the aluminium cans is coated with a thin layer of food-grade coating that helps protect the beverage, and that is not harmful to the health of the consumers.

Goal 6, Clean Water and Sanitation: We are all familiar with soft drinks and beer packed in aluminium cans. In recent years, more and more consumers are aware of the current environmental impact of packaging waste of bottled drinking water. As such, drinking water packed in aluminium cans ensures that the consumers have access to clean and safe drinking water, in a sustainable manner as aluminium cans are infinitely recyclable. Moreover, the manufacturing of aluminium cans emphasizes on effective use of process water, and proper treatment of discharged water, based on the 3Rs principle of Reduce, Reuse and Recycle.

Goal 8, Decent Work and Economic Growth: The continued growth of the usage of aluminium packaging as the sustainable solution of choice for both the customers and the consumers has helped fuel the growth of the industry. As such, the industry has helped to consistently promote economic growth and enhance job creation. This also leads to full employment without discrimination, where all employees can be a part of sustainable growth aligned with the organization.

Goal 12, Sustainable Consumption and Production: At present, the production of aluminium cans is very efficient use of resources because consumed aluminium cans can be endlessly recycled back into new aluminium cans. The used aluminium cans do not turn into waste, so this is a truly efficient resource circulation reducing aluminium smelting for the new resources. At the same time, manufacturers can drive society towards sustainability by educating them about waste management and encouraging waste separation at the source so that wastes can be turned into valuable resources.

Goal 13, Dealing with Climate Change: In large-scale manufacturing, it would be difficult to achieve zero greenhouse gas emissions, which is the main cause of climate change. However, our overall emission can be greatly reduced by using electricity generated by renewable solar energy rather than fossil fuel that pollutes the environment.

Goal 14, Marine Resources: As aluminium cans are infinitely recyclable, used beverage cans (UBCs) retain high value in the recycling value chain. As such, this reduces the tendency of UBCs becoming unwanted waste, and reduces the tendency of UBCs flowing into the ocean and affecting marine resources. In Thailand, there is a program aimed to take back used aluminium cans, such as the Aluminium Loop Recyclig Programwhich takes UBCs and loops them back into new cans endlessly.

Goal 17, Sustainable Development Cooperation: Sustainable aluminium can production requires close cooperation with our partners to make aluminium cans truly 100% recyclable. We need a high level of collection, high quality UBCs, state of the art recyclers, and state of the art rolling mills. Fortunately for Thailand, we have all of that within the country. As such, Thailand can be a model for the most efficient and effective Aluminium Can Closed-Loop Recycling, a truly circular economy. Aluminium Can Closed-Loop Recycling, a truly circular economy.

In addition, there is close cooperation among the government sector, associations, and various agencies related to environmental protection. For instance, there is the cooperation to promote the production of recyclable beverage packaging between the Ministry of Natural Resources and Environment (the Department of Environmental Quality Promotion and Pollution Control Department), Mahidol University, Resource Management for Sustainability (3R) Foundation, Thai Beverage Industry Association, Thai Beverage Can Ltd., UACJ (Thailand) Co., Ltd. and Anglo Asia Group (Thailand) Co., Ltd. to support an eco-friendly packaging production. Such cooperation can drive the circular economy through close cooperation between government agencies, the private sector, non profit organizations, and community to promote sustainable production and consumption, as well as sustainable waste management.

As you know, aluminium cans make the beverage fizzy, refreshing, and fast cooling. But more importantly, aluminium cans are 100% fully recyclable, allowing every part of the cans to infinitely turn into new aluminium cans. This is what manufacturers try to educate consumers to be able to properly handle used aluminium cans.

The eco-friendly packaging and production processes that minimize the impact on the environment, along with educating consumers on waste management, employment promotion, and income distribution in society all reflect that the environmental and social concerns are fully responsible by the producers leading to economic sustainability.

Thank you for the information from Thai Beverage Can Ltd., a manufacturer of aluminium cans and lids who sheds the light on sustainable development.

MOU signing ceremony for promoting the production of recyclable beverage packaging between the public and private sectors.

With the current global trend towards sustainable development, how do aluminium cans contribute to sustainability from an SDGs perspective?

Recycle, Upcycle, and Downcycle – how do these 3 processes differ? Let’s learn together to manage used materials correctly and appreciate their value.