Opening up perspectives… The private sector joins forces for EPR

Everyone is contributing to the environmental problems we face today. As consumers start changing their perspectives, what are the producers doing about it?

Before becoming the aluminium cans we’re familiar with. There are production processes they must go through. Ever wondered how the aluminium cans holding your drinks are made? What’s the production process they go through? Let’s dive into it together in this article.

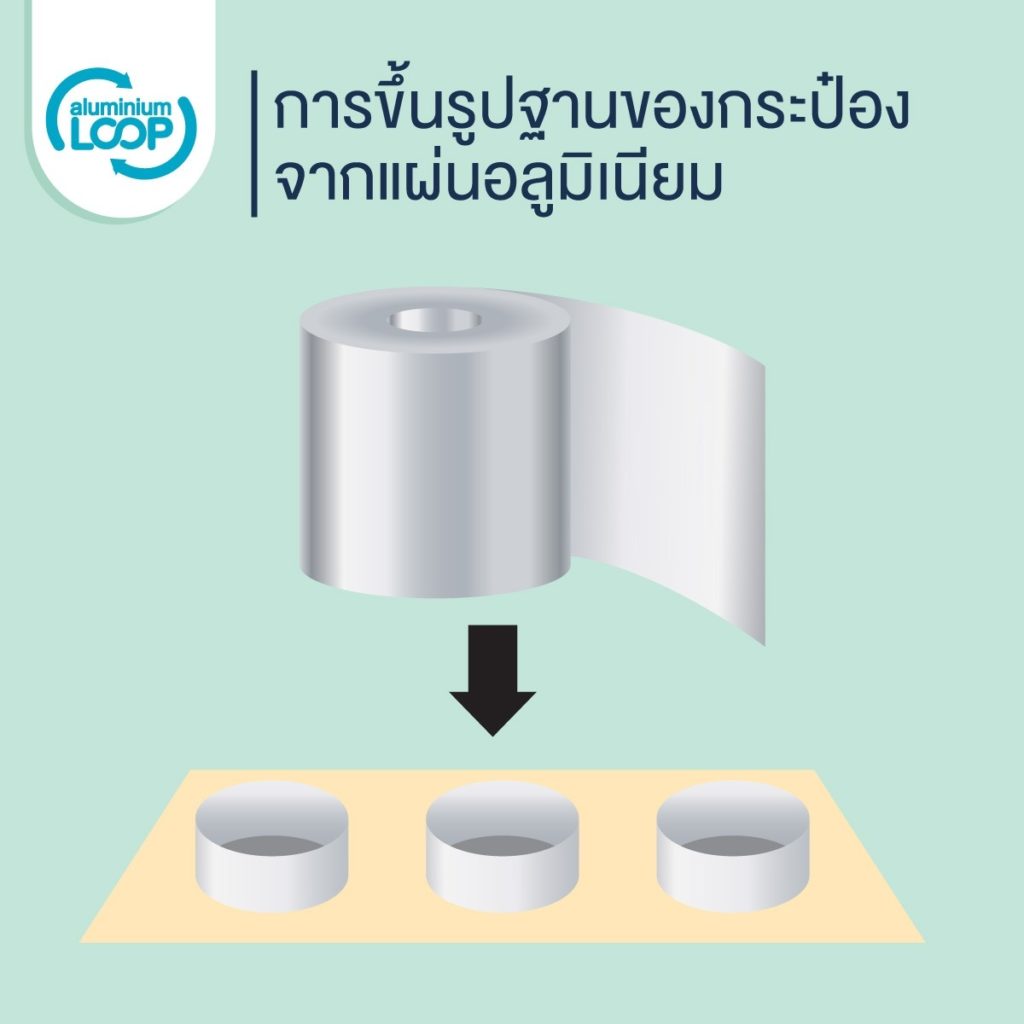

Starting from the raw material preparation like Aluminium Coil, which is over 69% recycled aluminium melted, cast into logs, and then rolled into sheets, these aluminium rolls then undergo several steps before being sent to the can manufacturing plants.

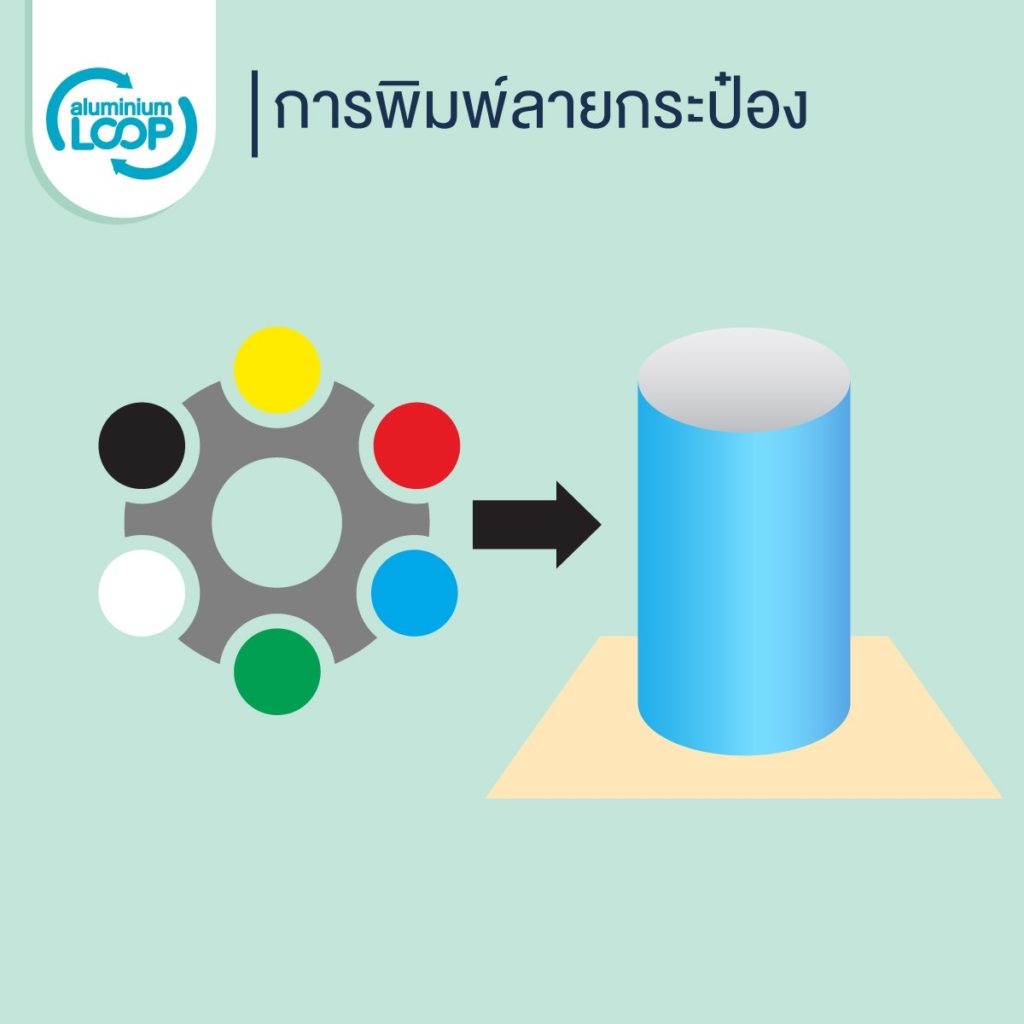

The production process of aluminium cans is divided into 2 main parts: the can body and the can end, each with its separate production process, which are then assembled after the drink has been filled.

*Bisphenol A (BPA) is a chemical added to various products and food containers, like plastic milk bottles, where it helps make the plastic stronger and more flexible. BPA is also used as a lining inside canned food containers to prevent erosion and corrosion. However, BPA can leach into the body from food that’s been in contact with containers using this substance, causing various health issues, whether through inhalation (headaches, nausea), skin contact (redness, itching), or ingestion (nausea, vomiting), leading to various diseases such as cancer, diabetes, heart disease, etc.

**BPA Free means the product doesn’t contain BPA, making it safe for consumers eating food from these containers. You can be confident that BPA Free containers are safe for food and drinks, and no harmful substances will leach into the food, even when heated.

Aluminium cans and their ends are sent separately to the beverage filling plants and are assembled after the beverage is filled using a Can Seamer machine in an overlapped manner, ensuring a tight seal between the can body and the end.

Making each new aluminium can is not an easy task. However, aluminium can manufacturers are highly aware of consumer safety and experience, giving significant importance to every step of the production process.

Despite the numerous steps involved in the production of aluminium cans, the result helps significantly reduce the use of natural resources through 100% recyclable used aluminium cans, leading to new cans ready for use in an endless cycle, known as “Closed Loop Recycling.”

Thanks for the valuable information from Thai Beverage Can Co., Ltd.

Everyone is contributing to the environmental problems we face today. As consumers start changing their perspectives, what are the producers doing about it?

Consumers have a key role in waste separation after consumption to make sure it goes to the right and effective disposal places.

What is the concept of a sustainable consumption society, and how can you be a part of it? Let’s learn together how to sustain our world.